In industrial environments where pumps and rotating equipment operate continuously under pressure, even the smallest component can have a major impact on performance. One such critical component is the mechanical seal. Designed to prevent leakage, reduce friction, and protect equipment integrity, mechanical seals play a vital role across industries such as manufacturing, mining, water treatment, food processing, oil and gas, and chemical handling. Choosing high-quality Mechanical Seals Australia solutions ensures reliability, safety, and long-term operational efficiency.

This guide explores what mechanical seals are, why quality matters, how they support pumps and rotating equipment, and what to consider when selecting the right seal for Australian operating conditions.

Understanding Mechanical Seals and Their Purpose

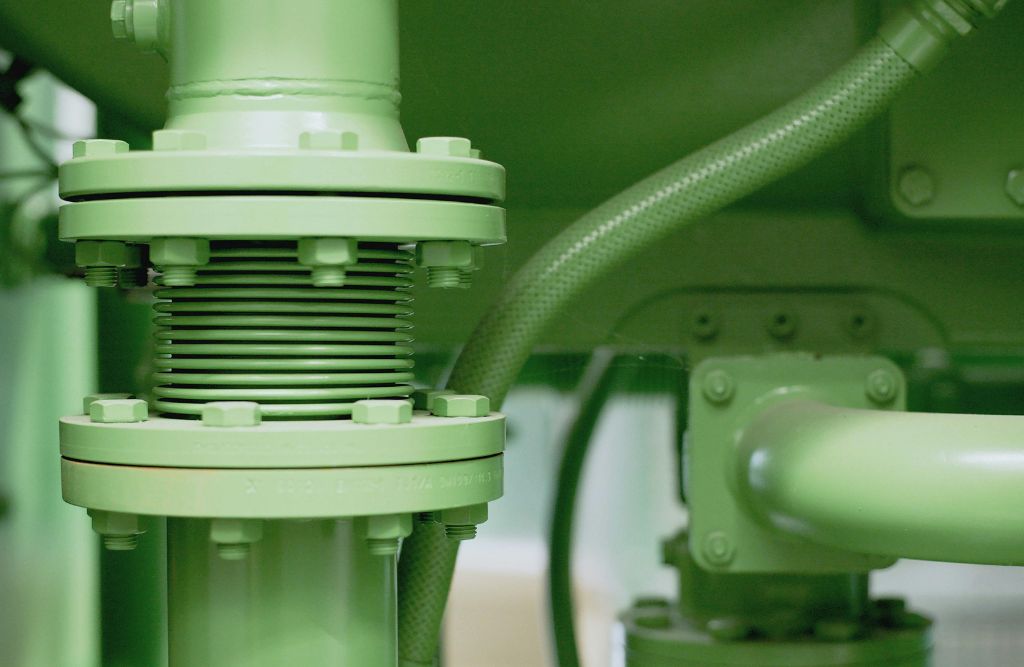

Mechanical seals are precision-engineered devices installed between rotating shafts and stationary components, most commonly in pumps and mixers. Their primary purpose is to prevent fluids or gases from leaking while allowing the shaft to rotate freely. Unlike traditional packing seals, mechanical seals offer superior sealing performance with minimal wear and reduced maintenance requirements.

Modern Mechanical Seals Australia suppliers provide seals designed to withstand extreme temperatures, high pressures, corrosive chemicals, and abrasive materials. This makes them indispensable for industries where downtime or leakage could result in safety hazards, environmental damage, or costly production losses.

Why Mechanical Seals Are Essential for Pumps and Rotating Equipment

Pumps and rotating equipment are the backbone of many industrial processes. Without effective sealing, these systems would suffer from fluid loss, contamination, and premature failure. Mechanical seals deliver several advantages:

- Leak prevention: Ensures safe handling of liquids and gases

- Improved efficiency: Reduces friction and energy loss

- Equipment protection: Minimises shaft and bearing wear

- Compliance: Helps meet safety and environmental regulations

High-performance Mechanical Seals Australia products are specifically engineered to match local industry demands, ensuring compatibility with Australian standards and operating environments.

Types of Mechanical Seals Commonly Used in Australia

Understanding the different types of mechanical seals helps in selecting the right solution for specific applications.

1. Single Mechanical Seals

These are the most commonly used seals, ideal for clean, non-hazardous fluids. They are cost-effective and easy to maintain.

2. Double Mechanical Seals

Designed for aggressive, toxic, or high-pressure applications, double seals provide an extra layer of protection and enhanced reliability.

3. Cartridge Mechanical Seals

Pre-assembled and factory-tested, cartridge seals simplify installation and reduce the risk of errors. They are popular across Australian industries seeking reduced downtime.

4. Split Mechanical Seals

These seals can be installed without dismantling equipment, making them ideal for large pumps or hard-to-access machinery.

Reputable Mechanical Seals Australia providers offer all these options, often with customisation to suit unique operational needs.

Materials Used in High-Quality Mechanical Seals

Material selection directly affects seal performance and lifespan. Mechanical seals typically consist of two main components: seal faces and secondary sealing elements.

- Seal Faces: Common materials include carbon graphite, silicon carbide, and tungsten carbide, chosen for their durability and low friction properties.

- Elastomers: Materials such as Viton, EPDM, and PTFE are selected based on chemical compatibility and temperature resistance.

- Metal Components: Stainless steel and specialty alloys provide corrosion resistance and structural strength.

Australian conditions—such as exposure to harsh chemicals, high temperatures, or abrasive mining materials—make material quality especially important when sourcing Mechanical Seals Australia solutions.

Key Industries Relying on Mechanical Seals in Australia

Mechanical seals are used across a wide range of sectors, each with its own performance requirements.

- Mining and Resources: Handles abrasive slurries and extreme operating conditions

- Water and Wastewater: Prevents leakage and contamination

- Food and Beverage: Ensures hygienic, leak-free processing

- Oil and Gas: Manages high pressures and hazardous fluids

- Chemical Processing: Withstands corrosive substances safely

In all these sectors, Mechanical Seals Australia suppliers play a crucial role in keeping operations safe, efficient, and compliant.

Factors to Consider When Choosing Mechanical Seals

Selecting the right mechanical seal involves more than just matching dimensions. Key considerations include:

- Operating pressure and temperature

- Fluid type and chemical compatibility

- Shaft speed and alignment

- Environmental and safety requirements

- Maintenance access and downtime costs

Experienced Mechanical Seals Australia manufacturers and distributors often provide technical support to help businesses choose the most suitable seal for their application.

The Importance of Quality and Compliance

Inferior mechanical seals may appear cost-effective initially but often lead to higher long-term expenses due to frequent replacements, unplanned downtime, and equipment damage. High-quality seals are precision-engineered, tested, and manufactured to meet strict quality standards.

Australian industries also need to comply with environmental and workplace safety regulations. Using certified Mechanical Seals Australia products ensures compliance while reducing the risk of leaks, spills, and operational hazards.

Maintenance and Best Practices for Longer Seal Life

Even the best mechanical seals require proper installation and maintenance to perform optimally. Best practices include:

- Ensuring correct alignment during installation

- Using clean, compatible fluids

- Monitoring operating conditions regularly

- Replacing worn components promptly

- Following manufacturer maintenance guidelines

By working closely with Mechanical Seals Australia specialists, businesses can extend seal life and improve overall equipment reliability.

Why Choose Australian Mechanical Seal Suppliers

Local suppliers offer several advantages over imported alternatives. They understand regional industry requirements, environmental challenges, and compliance standards. Additionally, Australian suppliers provide faster delivery, technical support, and custom-engineered solutions.

Choosing trusted Mechanical Seals Australia providers means access to expertise, high-quality materials, and products designed specifically for local operating conditions.

Final Thoughts

Mechanical seals may be small components, but their impact on pumps and rotating equipment is immense. From preventing leaks to improving efficiency and protecting valuable machinery, high-quality mechanical seals are essential for modern industrial operations.

By investing in premium Mechanical Seals Australia solutions, businesses can reduce downtime, lower maintenance costs, and ensure safe, efficient performance across a wide range of applications. Whether you operate in mining, manufacturing, water treatment, or chemical processing, the right mechanical seal can make all the difference in achieving long-term operational success.

Leave a comment